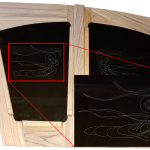

I like to talk about workmanship practices, quality of materials, and design philosophy. Under workmanship practices all hinge flaps and screws are hidden except the barrel of the hinge. Hidden hinges denote an elegant approach to any construction by caring about your technique and installation. And yes it costs more. The aesthetic gain is well …

Continue reading “DIFFERENCES IN WORKMANSHIP DESIGN AND PRACTICES”